Utility-scale Solar PV System Design

We design and build large-scale solar photovoltaic systems to meet your clean energy needs.

- Optimal Design

- Quick turnaround time

- Increase Efficiency

- Industry Leading Design Methodologies

Design To Meet Efficiently At Scale

rProcess Utility-scale Solar PV Design offers a comprehensive suite of services specifically tailored for large-scale solar projects, ensuring efficiency and optimal performance. Here’s how our Presales Designs can significantly benefit your project:

System Layouts:

Our team meticulously crafts system layouts tailored to the unique requirements of each utility-scale solar PV project. These layouts are designed with a focus on maximizing energy generation while considering factors such as site topography, shading analysis, and module orientation.

By providing detailed system layouts, we enable project stakeholders to visualize the spatial arrangement of solar panels, inverters, and other essential components, facilitating better decision-making and project planning.

Stringing Layout:

Stringing layout design is crucial for optimizing the electrical configuration of solar arrays, ensuring maximum energy harvest and system reliability.

We specialize in designing efficient stringing layouts that minimize energy losses due to shading, voltage drops, and other electrical inefficiencies. Our designs account for factors such as module specifications, inverter capacities, and string sizing requirements to deliver an optimized electrical layout.

Trenching Design:

Proper trenching design is essential for the efficient installation of electrical cables, conduits, and other infrastructure components required for interconnecting solar arrays and electrical equipment.

rProcess provides trenching designs that adhere to industry standards and regulatory requirements while minimizing excavation costs and environmental impact. Our designs consider factors such as cable routing, depth requirements, soil conditions, and site-specific constraints to ensure a smooth and cost-effective installation process.

Markup & Anchor Plans:

Markup and anchor plans are essential documents that outline the precise location of solar panel mounting points, foundation anchors, and other structural elements within the project site.

Our team develops detailed markup and anchor plans that facilitate accurate installation and alignment of solar arrays, minimizing errors and rework during the construction phase. By providing clear guidance on anchor placement, orientation, and spacing, we help ensure the structural integrity and long-term reliability of the solar PV system.

Overall, rProcess Utility-scale Solar PV Design’s Presales Designs offer a comprehensive package of services aimed at optimizing the design, layout, and installation of large-scale solar projects. By leveraging our expertise and attention to detail, project developers can minimize risks, maximize energy yield, and ultimately achieve greater success in their utility-scale solar ventures.

Utility-scale Solar PV Design process at rProcess

Customer fills the Design Request Form or loads the project in specific CRM Dashboard

This is the initial step where the customer provides necessary information such as site details, energy requirements, and any specific preferences or constraints through a designated form or dashboard in the CRM (Customer Relationship Management) system.

rProcess QA Team Reviews the Inputs and Passes it to the Design Team

Once the design request is received, it undergoes a quality assurance (QA) review to ensure that all necessary information is provided and accurate. The QA team checks for completeness and correctness before passing it on to the design team.

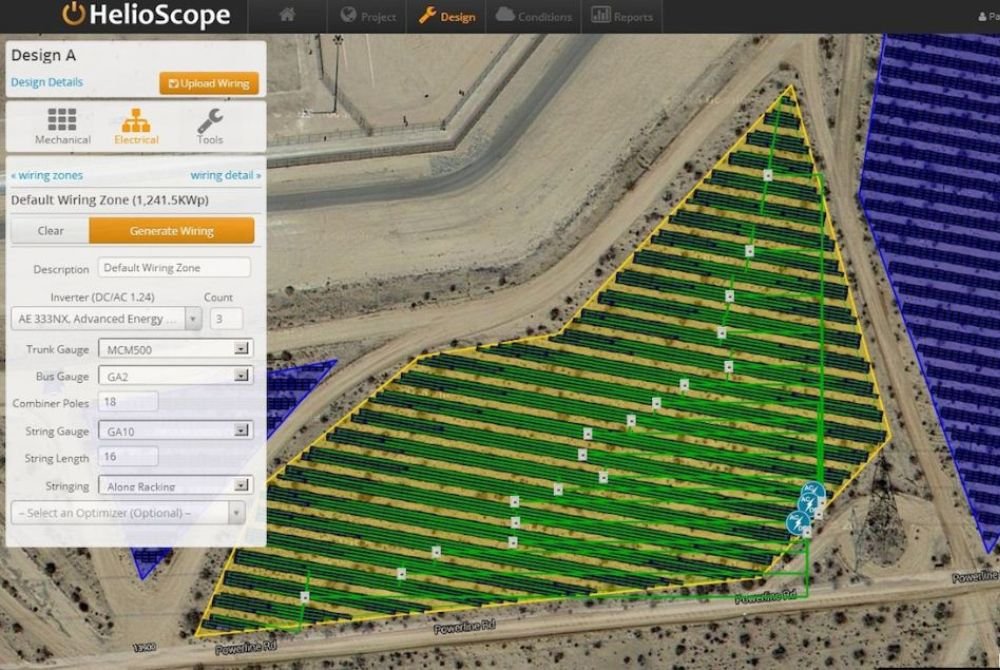

Design Team Does PV Layout Based on Inputs in Solar Online Tool & Asks for Approval

The design team utilizes specialized software or online tools designed for solar PV (photovoltaic) system design such as Homer Pro, PVSyst or others. They input the project specifications, site details, and other relevant parameters to create a layout for the solar PV system. This layout includes the positioning of solar panels, inverters, and other components. Once the layout is prepared, it is submitted for approval.

After approval, all the Required Drawings are Completed in CAD Tool

Upon receiving approval for the PV layout, the design team proceeds to create detailed drawings using Computer-Aided Design (CAD) tools. These drawings include technical diagrams, electrical schematics, and structural layouts necessary for the approval & installation of the solar PV system.

Drawing Files are Shared in the Shared Drive & Status is Changed in CRM

Once the drawings are completed, they are converted into PDF format for easy sharing and accessibility. The PDF files are then uploaded to a shared drive or document repository for internal access. Additionally, the status of the project is updated in the CRM system to reflect the progress made in the design phase.

Upon Client's Approval, the Project is Changed to Completed Status

The final step involves obtaining approval from the client or customer based on the provided drawings and design. If the client approves the design, the project status is updated to "completed" in the CRM system, indicating that the design phase of the PV solar project has been successfully finished and is ready for implementation.

Get Quote

Customer Testimonials

Why Choose rProcess For Utility-Scale Solar Design?

Experienced and Qualified Team

Our seasoned professionals bring a wealth of experience and expertise to the table, ensuring that every aspect of your project, from PV Site Layout to Anchor Layouts, is handled with precision and care.

Proven Track Record

With a history of successful utility-scale PV projects under our belt, we have demonstrated our ability to deliver results consistently. Clients can trust in our track record as evidence of our capabilities.

Timely Response

With an average project turnaround time of less than 72 hours, we help you stay on track with your timelines.

Commitment to Quality

Quality is at the forefront of everything we do. From PV Site Layout to Trenching Layout and beyond, we prioritize attention to detail to ensure that each project meets the highest standards of excellence.

Competitive Pricing

We understand the importance of cost-effectiveness in utility-scale projects. That's why we offer competitive pricing without compromising on the quality of our services, ensuring maximum value for our clients.

Client-Focused Approach

Your satisfaction is paramount to us. We tailor our services to meet your specific needs, offering flexibility through various engagement models, including Subscription, Pay per Bundle, Pay per Project, and Hourly Rate options.

Utility-scale Solar PV Design Service - FAQ

Specialized design for utility-scale solar projects is important because it maximizes efficiency, reduces costs, ensures seamless grid integration, enhances long-term performance, minimizes environmental impact, and ensures compliance with local guidelines and standards.

We have expertise in handling designs with system sizes up to 5GW. Following are the typical deliverables:

- Presales

- System Layouts

- Stringing Layout

- Trenching Design

- Markup & Anchor Plans

To ensure grid compatibility in utility-scale solar PV designs, we adhere to local grid connection standards and codes, ensure power quality, conduct interconnection studies, and consider implementing smart grid technologies. We also use advanced CAD tools to ensure optimal design.

Interconnection requirements for utility-scale solar projects typically involve studying grid capacity, voltage levels, and system stability. This entails coordination with utility companies and compliance with local regulations to ensure seamless integration into the existing power infrastructure.

Yes, we can accommodate specific customer requirements in utility-scale solar PV designs by utilizing advanced tools such as HelioScope, Homer Pro, and other CAD tools.

The typical timeline varies from 48 hours to 72 hours depending upon the system size and number of details provided.

Yes, our pilot team is always ready for deployment to handle tight project deadlines.

Yes, we can design AC & DC Single Line Diagrams and other electrical layouts to showcase compatibility with our inverters and other BOP components.