Product Design

Turning Ideas into Real Products

We provide complete solutions in product design & development ranging from Conceptual design, Sheet metal design to Finite Element Analysis and Geometric Dimensioning & Tolerancing, as per international standards, with very competitive price models

Expert Design Support for Complex Projects

Conceptual Design

Product Design

Simulation

Production Drawing

Design for Manufacturing & Assembly (DFMA)

Bringing 2D Ideas to 3D Life

We specialize in transforming 2D concepts into detailed, photorealistic 3D models ideal for rapid prototyping and digital manufacturing.

Conceptual Sketching

We assist in creating sketches or diagrams that are concisely annotated with short statements that describe the concepts, processes, and interrelationships of any mechanical / electromechanical designs.

3D Modelling

We are capable of converting 2D model to photorealistic 3D models for conceptualization, rapid prototyping, digital manufacturing, etc.

Mechanical Animations

Creating realistic 3D renderings of diverse mechanical goods and their components’ configurations, assemblies and modes of operation.

Surface Modeling

We provide surface modelling for mechanical, aeronautical & automotive components for visualization, procedural surfaces, validate imperfections, and apply smoothness.

Bringing 2D Ideas to 3D Life

We specialize in transforming 2D concepts into detailed, photorealistic 3D models ideal for rapid prototyping and digital manufacturing.

Design Detailing

We provide design detailing / modifications to the 3D models for solid, sheet metal, structural & plastic components.

Solid Components Design

We design components for CNC machining, Press Tool Design & electro-mechanical assemblies along with static & frequency analysis.

Sheet Metal Design

We design sheet metal components for developments, machining & electro-mechanical assemblies along with static & frequency analysis.

Structural/Weldments Design

We design structural members for various domestic & commercial designs with detailed framework, Building Information Modelling (BIM) & Bill of Materials (BoM).

Plastic Components Design

We provide design & simulation of plastic components for design validation & for manufacturing through injection Molding, Powder Metallurgy & Additive Manufacturing.

Bringing 2D Ideas to 3D Life

We specialize in transforming 2D concepts into detailed, photorealistic 3D models ideal for rapid prototyping and digital manufacturing.

Finite Element Analysis (FEA)

We provide FEA for various class of components on part & assembly level. Following are the various analysis we provide: –

- Static yield

- Frequency Analysis

- Linear Dynamic Analysis

- Nonlinear Dynamics Analysis

- Fatigue Analysis

- Failure Mode & Effect Analysis

- Topology Optimization

Computational Fluid Dynamics (CFD)

We provide CFD analysis for various class of environmental conditions. Following are the various analysis we provide: –

- Thermal Analysis

- Heating Ventilation & Air Conditioning (HVAC) and Electronic Cooling Simulation

Bringing 2D Ideas to 3D Life

We specialize in transforming 2D concepts into detailed, photorealistic 3D models ideal for rapid prototyping and digital manufacturing.

Drafting

We provide FEA for various class of components on part & assembly level.

Following are the various analysis we provide:

We work with various parameters such as :

- Production methods

- Drafting units – imperial & metric system

- Projection types – 1st & 3rd Angles

- Limits, fits, and tolerances of size, form, and position as per GD&T standards

- Indication of surface roughness and other heat treatments

- Machining Allowance

- Conventions used to represent certain machine components

- Inspection and testing methods

Specification of standard components

Tables for Bill of Materials (BoM), Tolerance Tables, etc.,

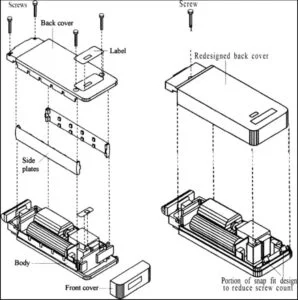

Design for Manufacturing & Assembly (DFMA)

We specialize in transforming 2D concepts into detailed, photorealistic 3D models ideal for rapid prototyping and digital manufacturing.

Design for Manufacturing

Our goal is to ensure the following: –

- Minimize part count

- Standardize parts and materials

- Create modular assemblies

- Design for efficient joining

- Minimize reorientation of parts during machining

- Streamline number of manufacturing operations/processes

- Define acceptable surface finishes

Have a project in mind?

Schedule a Call

Just One Call Away – Let’s Talk Solutions!

Call Us +91 99800 07732